Greetings, Lathe Ops, cutting

engineers, and aficionados of music recording and or

engineering:

R ecently, we were discussing the bedways of the

Scully lathes. I like how the trolley wheels ride on flat

surfaces that are claimed from the Aztec / Mayan pyramid-like

silhouette of the vee ways. In order to address a problem

with the Finish Cancel Trip signal (discussed below), I had

to remove the carriage. While it was off, I decided to do

a photo shoot to add to the

documentation on the ways.

As for the "ways" they made

them, these Scully pyramids "boogie" "mesas." Notice,

also, how the wheel at the tail end of the bed goes. " \_/," so as

to hug, with discouraged, but not disallowed, wiggle, providing

the rudder of the carriage an even footing

These Finish Cancel Trip micro-switches were

nearly boggling me mind, for a while. I know

that they say to check the connector, but it was the last

connector I'd ever had thought of, since it is normally hidden,

seldom disturbed, and was still tightly connected. The

micro-switches are bundled in a snake, which mates with another

section of snake, under the lathe bed. One of the pins on

the male connector, there, was invisibly oxidized enough to sort

of fall asleep, electrically (or that's what I've decided).

Once I unplugged that connector and replugged it, together, it

worked. I put some Caig DeOxit on there and plug-cycled it

about 20 times. Have been doing contact maintenance on all

the surfaces. Alas, Mr. Grundy did not restore this vintage

machine before I bought it. (Note: Caig D5 and Gold

(follow-up) done to all contacts, September 2014, with immediate

improvement in logic supply efficiency).

Before I found the solution, I

naturally checked every transistor and integrated circuit on all

seven boards.

The micro-switch showed

continuity when tripped. The wire ("W") on the pin of the

turntable speed selector switch,

which is designated for the

12" Finish Cancel Trip,* was showing continuity with its

destinations in the card cage and

with ground, when

selected.

Yes, I did have the ability

to do manual mode lock-out cutting at the end of a side, but when

the thing is working and is

automated to precise RIAA

disc-diameter specification/suggestions, without the operator

breaking more of a sweat than,

say, doing the work

involved in selecting a side on a juke box, I could not rest until

the answer was found and the problem

solved. (rest,

resumed)

* Finish Cancel Trip

happens when the carriage has been fed far enough to the left that

the micro-switch, which causes the

Feed to be canceled,

without stopping the turntable or lifting the head before a

complete revolution and a half has occurred,

thereby creating a locked

groove at the end of side, is tripped.

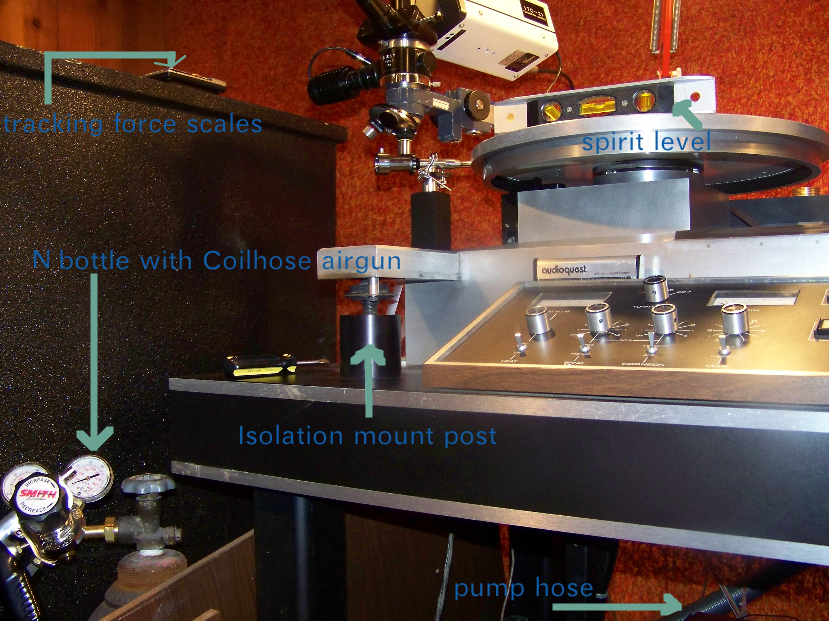

I was concerned about the amount

of turntable runout, and, when the tightening and loosening of the

platter hold down bolts was insufficient to tame the variance of

flatness during the revolution of the platter, I resolved to

check the isolation mount posts for their correct

adjustment. Fortunately, only one of them was not

correct. One can loosen a nut under the steel

weldment and, after removing the aluminum shroud, rotate the

isolation mount post to raise or lower the given corner of the

A-table.

Bottle regs: "Lefty

Loose and Righty Tight," for off.....

Normally, two assistants

are required so that each end of the A-table can be supported

while the spirit level is made to

rest horizontally and you

rotate the coffee mug-shaped post to make the necessary

adjustment. Then you tighten the nut,

underneath the weldment,

and replace the shroud...

In this case, the other

posts were correct, already, so I was just able to rotate it by

myself, with only some difficulty -

"sweat equity?," but with

the WPI (work progress indicator) that the air bubble had become,

once again, centered throughout

the turntable

revolution.

It is now holding that corner up flat, and the depth feeler is showing

the runout to be, once again, reasonably in spec. The

goal is +/- 1 mil during one slow

revolution (by hand).

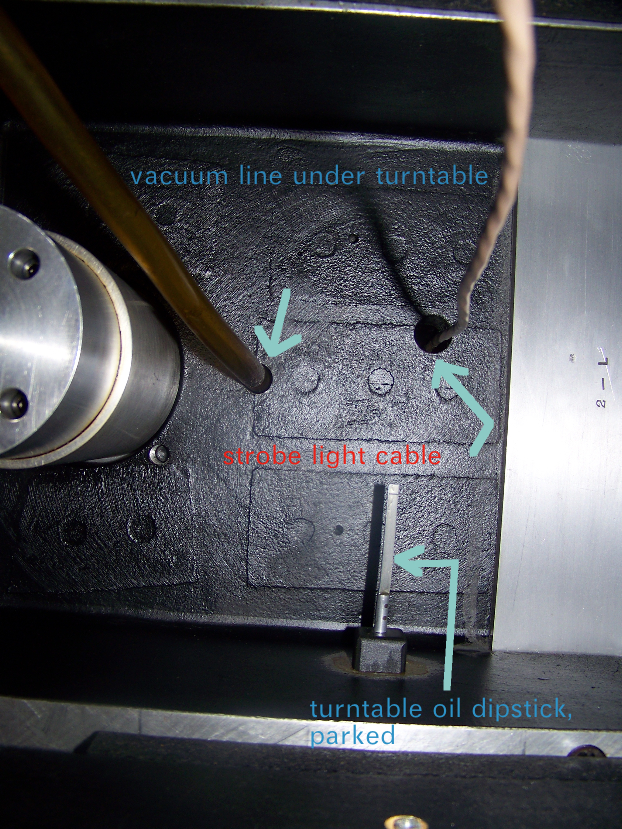

While doing the photo shoot, I thought I'd

document the captive suction mounting vacuum

line.

The original version of the LS-76 was like the Neumann VMS lathes

which have a vacuum tower above the table, with a hose terminating

in a chuck which is put on top of the spindle, once the blank

workpiece is in place. This causes vacuum pressure to

be an invisible mandrel,

using the system of air canals that provide suction mounting

through holes in the platter. There was no edition of

the LS-76 manual which

demonstrated the captive vacuum line, but it is in this Scully

(#656), and also, at least, on #660.

...and, topside (shown,

below - taken while platter was removed, of course):

There are three threaded holes on the top of the turntable that

the platter bolts onto. The dipstick hole is just showing

over the rear edge of the spindle.

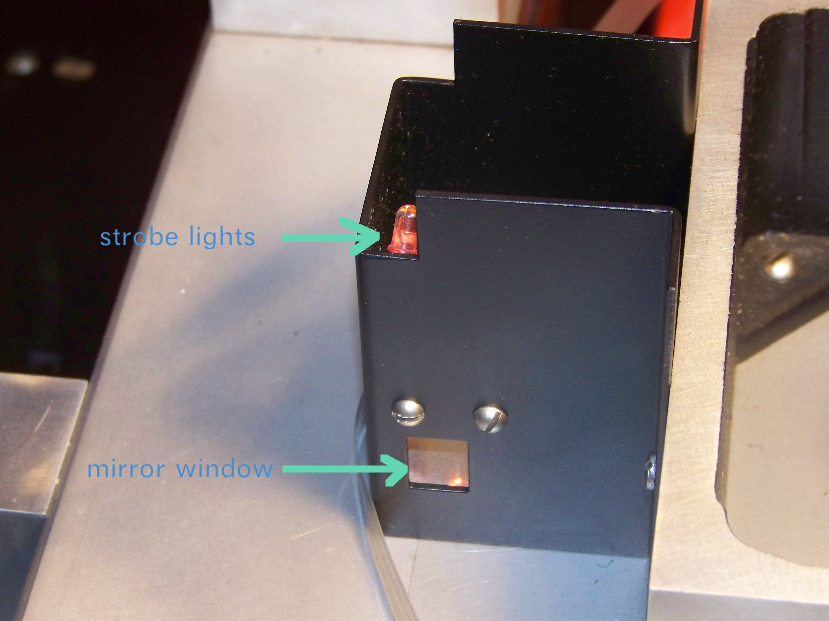

Here's a view (below) of the strobe light mirror

window, next to the turntable.

The clear mylar belt used for turntable rim drive is resting next

to it. The top of this housing is normally covered by

the platter, and the light bulbs are thereby

concealed. But the little window looks in on a tilted

mirror, which reflects the light

display from above for non-glaring optical confirmation of steady

revolution at the selected speed. This is rather like a

periscope.

The article, only half-jokingly titled, He Who Lathes Best,

mentions that Scully made a lathe for the Navy to use in a

submarine.

Perhaps there was some cross-polination of design and engineering,

over the years, between Westrex, Scully, The Armed Forces, and

Tom Dowd. One can dream, can't he?