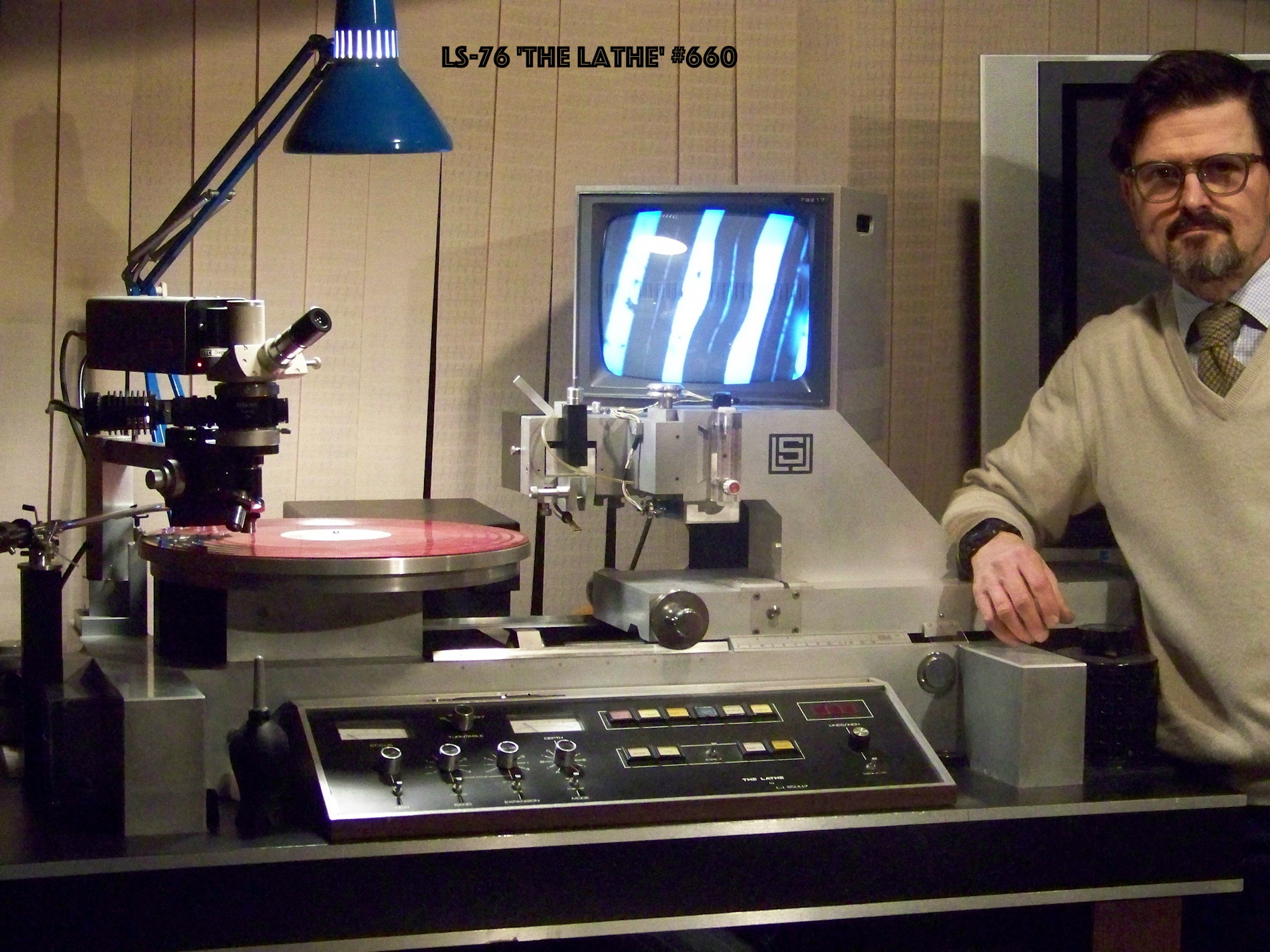

'THE LATHE' (aka LS-76) #660, was originally used by Eva-Tone in their Clearwater, Florida plant, for mastering their flexible disks called, Sound Sheets, that were stapled into magazines...

This lathe was barely functional and not fully complete when I acquired it from then-owner flozki who had it parked in his neighbor's barn in the countryside of Switzerland. It has now been restored to finely-tuned operation and had all of its missing features replaced.

Refurbishments include:

• new (crystal-locked) turntable servo drive board viewtopic.php?f=3&t=94

• rebuilt tt motor (by MDI Precision Motor Works) Eva_Tone/74C00_tach.JPG

• new chrome-plated, steel thrust ball for turntable axle viewtopic.php?f=3&t=76

• logic supply crow-bar protection-circuit viewtopic.php?f=3&t=178

• modification of feed clock timer network viewtopic.php?f=3&t=219

• modification of LF-presence corner frequency on Variable Pitch board to improve lathe-automation during passages with strong bass content:

viewtopic.php?f=3&t=177&p=259#p263

• recap. of power supply (including large stud-mount types) with new regulators, and fuses added to the bipolar op-amp supplies

viewtopic.php?f=3&t=199

• all 70+ DIL chips replaced with ones that test 'good' on ABI Chip Master and Linear Master ZIF devices

• (NOS) JVC 4MD-20X (4-channel / stereo) cart with 4DT-20X (Shibata diamond stylus) on the 12” Stax tonearm

• custom chip tube nozzle made by George Alexandrovich, Sr. (of Fairchild)

• new rubber tubing for vacuum lines of chip tube and turntable

• NOS Spectrol potentiometer for 'Lines / Inch' adjustment

• new, seamless, ultrasonically-welded Mylar turntable-rim belt* and Mylar feedscrew-pulley belt (made by OEM, Butler Precision Belts).

• NOS Brooks-Mite gas flow reduction valve/meter (w/brushed glass ball floating indicator, of SCFH) for Helium-cooling cutting heads

• Nikon microscope with swiveling boom arm, as well as correct-vintage Ikegami video camera and monochrome CRT monitor, added, along with original wood-grain panels and black Formica shrouds for bottom of steel weldment, from #654 (the LS-76 from Rhythm Shack, in Miami)

• clone of the original LS-76 black wooden pedestal used for placing the camera monitor on the lathe table, behind the bedways, custom made by an ebay carpenter

* L. J. Scully designed THE LATHE to use a belt-driven turntable so that motor rumble (sound and vibrations) won't telegraph to the platter, which keeps it out of the groove. By using a seamless Mylar belt, there's no once-around disturbance, and the coefficient of friction precludes slipping. Kapton won't work in this application because its friction isn't quite sufficient, resulting in occasionally-audible flutter. Not so with the Mylar belts. Btw, the ply of the belt as well as the exact outer diameters of the capstan sleeve and the recessed platter rim (that the belt goes around) are crucial factors in the effective speed since the circuit that controls the turntable motor is only getting feedback from the tachometer (as 20 µs duty-cycle pulses), rather than from the turntable, itself. The diameters of the capstan sleeve on the motor shaft, and the rim of the platter that the belt goes around, are slightly augmented by the ply of the belt, so I made sure to order the correct, 3.0 mil belts, which make the strobe pattern lock without any drift, and I have inventory of these new belts for the future, though they last for decades in normal use.

________________________________________________________________________________________________________________________

Fully functional original L. J. Scully 1976-era disk computer circuits, based on Capps II pitch and depth computer with absolute polarity-discernment of control audio to permit nestled groove-turns...

Base pitch settings available between 100 and 600 LPI.

Turntable runout shows +/- ½ mil using depth-feeler gauge at the 15" diameter of the revolving platter.

This lathe's tone arm was converted from a 10" to a 12" by the addition of a custom fabricated 'stand off block' and a vintage Stax arm and headshell

Eva_Tone/Stax-12_660.jpeg

...the DIL chips across the seven cage cards are socketed for easy testing and replacement, and the through-hole components are easy to work with and, though in many instances may now be described as 'obsolete", or are only available in surface-mount form, they are, yet, obtainable on ebay, in good - to - NOS condition. Other circuits in this TTL gate / hybrid-op amp disk-mastering computer that are rare or hard to decipher have been solved via reverse-engineering and cloning the potted-module DATEL 'Econoverter' 6-bit A/D converter and ADC-89A8B 8-bit A/D converter (which are only used for lathe-automation and LPI-display signals, leaving program audio, of course, always-analog and unaffected by the lathe's converters) and by data-copying to NOS blank Signetics PROMs from known-good master device PROMs for the Display Processor's three, 7-segment l.e.d. numerical arrays for LPI display, which, by the way, is switchable, on-the-fly, between the selected Base-Pitch setting and 'live' expansions (whether logically (i.e., resulting from automation audio signals), or manually, invoked. The Expand switch on the console allows manual override to, both, fixed, and variable, pitch to operator-specified LPI. Manual overrides to variable pitch and variable depth allow de-expansion from Basic settings during quiet passages for optimum mastering.}

________________________________________________________________________________________________________________________

Ortofon drive package associated with #660 + (2) brand new Ortofon GO741 550-Watt cutting amplifiers, with new-old-stock, empty PCB cards that were freshly populated with components and calibrated to each other in 2015 (and, still, unused, other than for periodic testing), by the same Ortofon engineer who originally made them, Torben Rønne, and (1) GE741 refurbished dual power supply, with new stud mount caps by Kemet and new bleeder resistors. Also used with these amps is an Ortofon STL-732 treble limiter that takes its side-chain signals from each cutting amp, allowing the initial transient of loud treble through, and then quickly clamping any persistent, high velocity-making signals with a 2nd-order Bessel filter with a variably 'sliding' roll-off frequency, which is an effective remedy against pickup-cartridge tracing distortion, without muffling musically-significant treble bursts.

Both cutting amps chassis and that of the dual psu, as well as the STL-732, are 19" rack-mountable. The original Pabst AC fan for each amp and PSU chassis has been replaced with a 16-dB Thermaltake DC fan for quiet operation near lathe.

The GO741 cutting amplifier has the best frequency and phase response of all gramophone recording systems in the world. These amps can be used for CD4 quadraphonic cutting at half speed, when using the DSS731 cutting head, which has useful signal response up to 26 kHz. A half-speed-cut's 26-kHz bandwidth allows a full-speed-playback bandwidth sufficient for the ultra-sonic frequencies used in encoding and decoding the two extra, difference signals of a CD-4 recording's modulated carrier signal. The reason for using such an extended flat frequency and phase response in stereo records, which require no ultra-sonic decoding, is audiophile-quality 'transparency', similar to recording digital audio at higher sampling rates, where higher in-band frequencies don't get perturbed by close proximity to a steep roll-off filter.

Here's what the A channel chassis looks like inside (the original input transformers are still mounted, but have been bypassed for clearest sound. Can be put back if desired, and they're not bypassed in the main system down the hall, in Control C, since they sound really good. But for purity, the elimination of the iron stage is preferable when the sonic signature of the program being mastered to disk is of the highest quality.) ________________________________________________________________________________________________________________________

+ DSS821 (green) stereo cutting head (in original wooden box) - the Holy Grail of stereo cutting heads because of the wide bandwidth (to 24 kHz), ruler-flat frequency response (+/- 1 dB), and extra power-handling capability over the previous DSS models. drive coils' DC resistances: 9.0 Ω ; 9.1 Ω

feedback coils' DC resistances: 189.1 Ω; 178.6 Ω

Here's the frequency and cross-talk response of a DSS731 cutting head powered by the GO741 amps (from the Ortofon

cutting head instruction manual): This vintage advertisement (below) shows Alan Blumlein's rocking-bridge design as implemented by Ortofon in a

cut-away schematic view of the insides of a Phonotec 'Phonohead' cutter. The green cutter for sale with THE LATHE,

however, is genuine Ortofon-made. ________________________________________________________________________________________________________________________

If you have questions about THE LATHE or Ortofon cutting systems, please write to: gosub2k@andrewhamiltonmastering.com

Thanks for looking - &rew